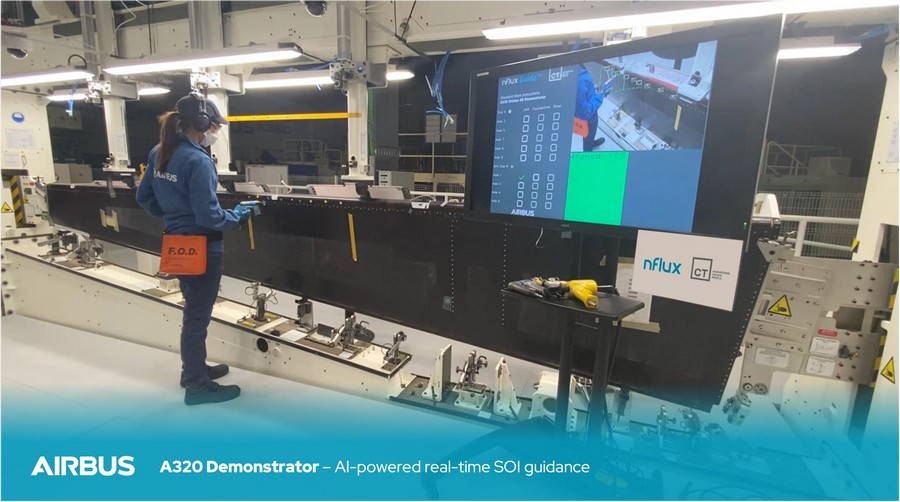

AIRBUS Spain is actively testing next generation technologies to evaluate their suitability to improve manufacturing operations. As part of these ongoing tests, Airbus in collaboration with CTI has recently conducted a successful technical trial of nFlux Guide™️, a Computer Vision assistant for manual operations.

It is worth remembering Airbus’ unparalleled commitment to innovation, which is responsible for major transformational achievements in commercial aviation, such as the Concorde: World’s fastest passenger aircraft), A300B4 (World’s first ETOPS compliant aircraft), A320 (World’s first fly-by-wire passenger aircraft) or A380 (World’s biggest passenger aircraft).

Airbus has successfully validated in a demo station of the A320 horizontal elevator an AI-powered computer vision solution delivered by CTI and nFlux which enables Airbus to monitor specific drill patterns and provide workers with live confirmation on choosing the right tool and bid size for the different holes in an assembly.

nflux Guide for assembly workers in manufacturing

nFlux Guide™️ supports assembly workers in their daily tasks and enables manufacturers, like Airbus, to better ensure procedure conformity in real time, which is a major step forward in Quality Management. Due to the high quality and safety standards at Airbus, ensuring procedure conformity is a key manufacturing concern, and by using nFlux technology, Airbus can support its workers to error proof operations in real-time.

Airbus, CTI and nFlux are now building on the successful results of the technical validation to gradually scale up the deployment across the factory.