nFlux Acuity™

The AI Powered Co-pilot

for Manufacturers

Acuity™️ is a digital workmate for supervisors, quality and lean engineers, and plant managers that uses computer vision to provide real-time visibility and historical analytics of manual assembly at their factories.

nFlux Acuity™️ is changing the game on how manufacturers approach quality management and continuous improvement by offer better digital tools to support their workers.

Lean how our solution works and how our customers are using it to build their factories of the future.

How does it work?

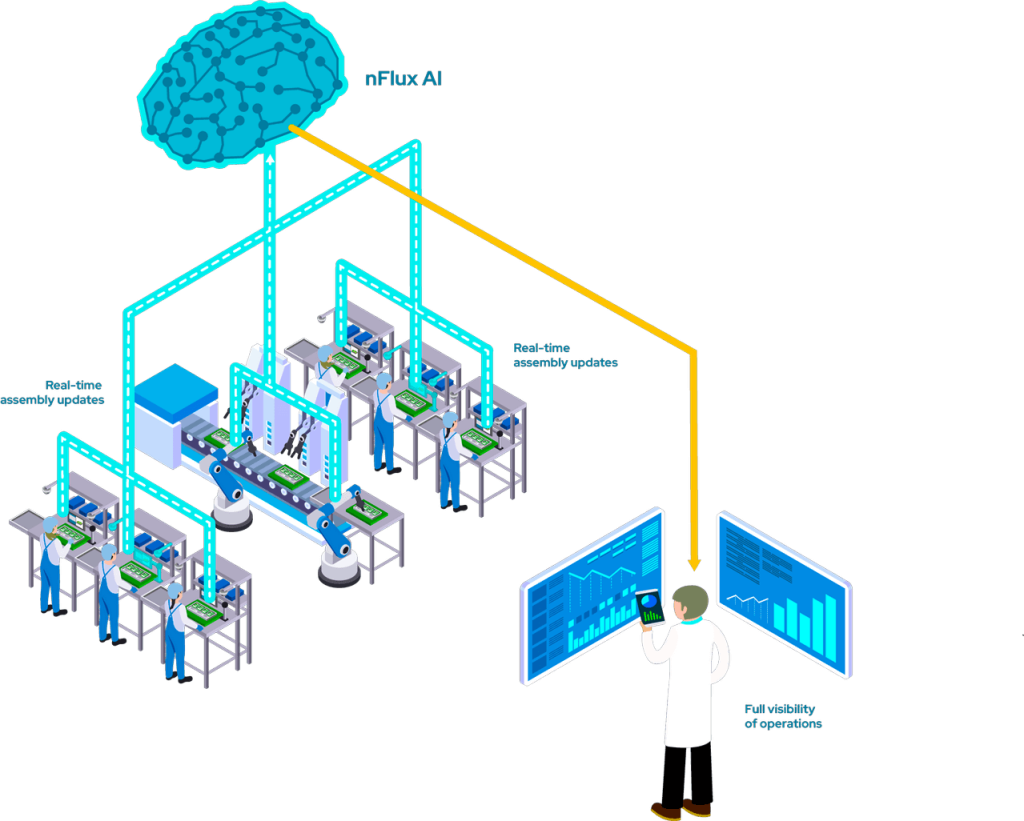

nFlux Acuity™ leverages the findings obtained by nFlux Guide™ to provide deep operational insights from manual assembly to supervisors, quality and lean engineers, and plant managers.

Acuity™ provides aggregated and anonymized insights, helping identify best and worst practices, effectively generating a virtuous improvement cycle. Any inefficiencies discovered can be quickly investigated to understand their root cause through video analysis.

Real-time progress updates also enable manufacturers to further feed the scheduling and planning systems for ultimate operational orchestration.

How does it add value?

nFlux Acuity™️

By equipping workers with nFlux Guide™, manufacturers also see tangible benefits.

Despite the hype around robotics and automation, manual labor still accounts for 70%+ of the production in manufacturing, so enabling workers to become a better version of themselves has a deep repercussion on productivity.

Leveraging the insights from Guide™, nFlux Acuity™ provides supervisors, quality and lean engineers, and plant managers with real-time visibility and analytics of their factory.

Acuity™ closes a 100 year old gap in visibility and enables more effective support of manufacturing workers in one or more geographies.

By equipping workers with nFlux Guide™, manufacturers also see tangible benefits.

Despite the hype around robotics and automation, manual labor still accounts for 70%+ of the production in manufacturing, so enabling workers to become a better version of themselves has a deep repercussion on productivity.

Leveraging the insights from Guide™, nFlux Acuity™ provides supervisors, quality and lean engineers, and plant managers with real-time visibility and analytics of their factory.

Acuity™ closes a 100 year old gap in visibility and enables more effective support of manufacturing workers in one or more geographies.

What are our customers saying?

Seeing the AI detect actions in real-time feels like magic. It is gratifying finding companies like nFlux that use technology to aid human workers and not to replace them.

Union's Representative aerospace oem

When people across the company see Guide™ in action they completely get it. I could easily see it becoming the new hammer for assembly workers

head of global excellence at electronics OEM

The simplicity of using AI and machine learning behind Guide™ has the potential of disrupting the incumbents in the field of Automatic Optical Inspection (AOI).

PLANT MANAGER AT ELECTRONICS OEM

nFlux Guide™️ and Acuity™️ suite of manufacturing AI assitance tools is changing the game in quality and productivity.

With less than 6 months of payback time, our customers are finding it a no-brainer to adopt nFlux!

Defect avoidance

34%

Rework Reduction

16%

Ramp up time

-47%

Training time

-52%