nFlux Guide™

The AI Powered Co-Pilot for Flawless Manual Assembly

Guide™️ is the workmate conducting procedure-driven assembly, that uses computer vision to provide front-line workers with step-by-step guidance and real-time error detection.

At nFlux we are transforming the way manufacturers approach worker training and quality control.

Learn how our solution works and how our customers are using it to build the factories of the future.

How does it work?

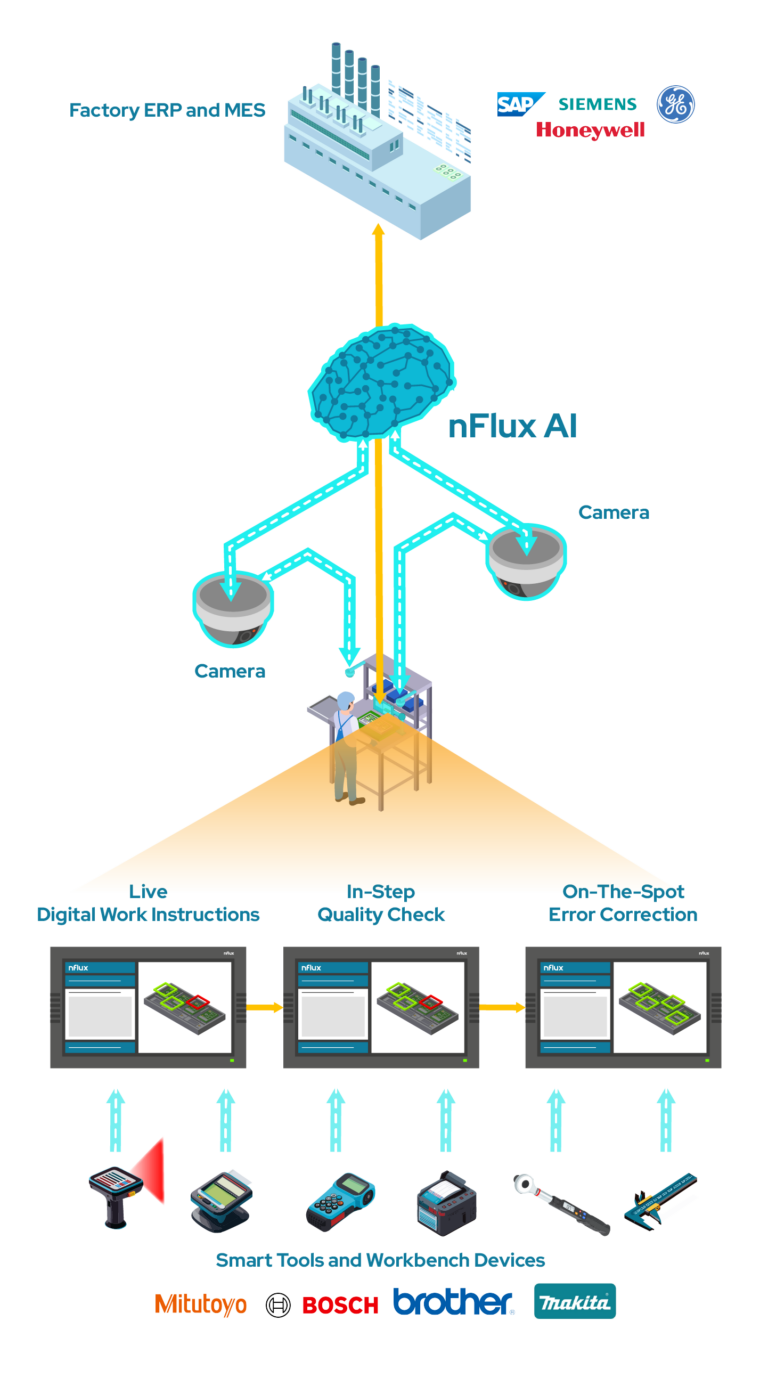

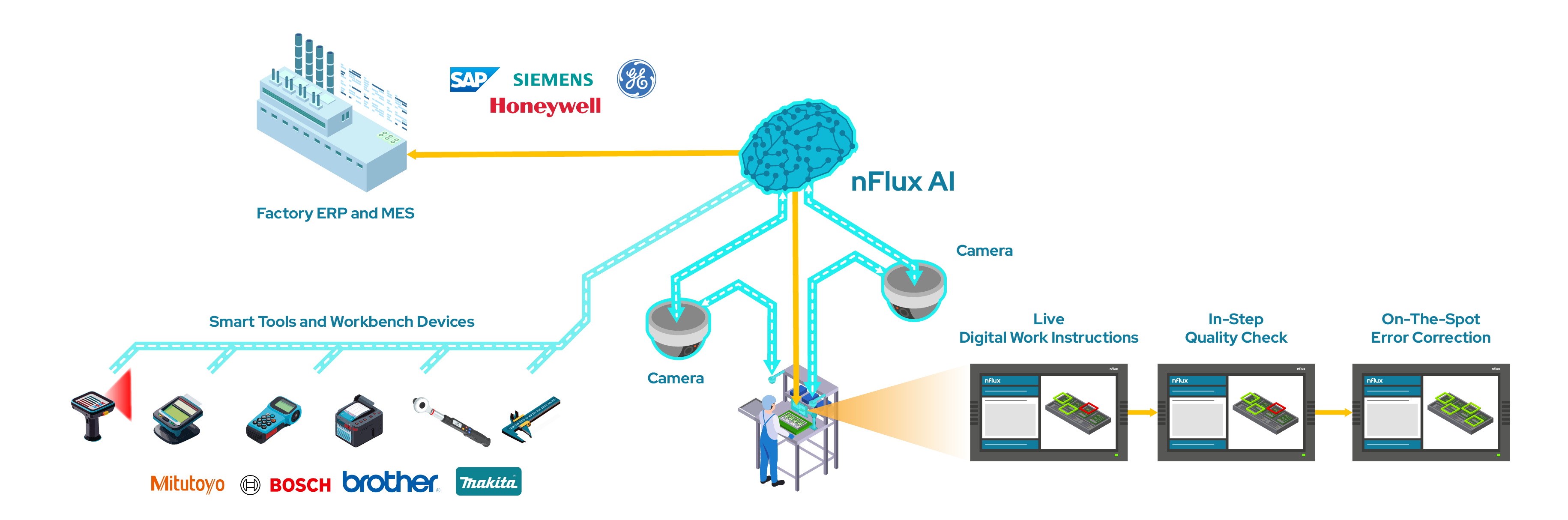

nFlux Guide™ uses computer cameras and artificial intelligence to observe and analyze assembly activities in real-time, matching them to Standard Operating Instructions, providing workers with seamless step-by-step Digital Work Instructions and detecting deviations as they happen for an instant quality fix.

By combining In-Step Quality Inspection with Smart Tool (Digital Calipers, Smart Screw Drivers, Barcode Scanners, etc.) and ERP/MES integration, manufacturers gain an unprecedented level of visibility and control over manual assembly activities.

Digital Work Instructions

Step-by-step Guidance

Smart-Tools Integration

In-Step Inspection

Demo of nFlux Guide™ working

How does it add value?

By providing real-time guidance, Guide™️ serves an additional pair of eyes for experienced workers and as a coach for trainees increasing effectiveness while reducing mental fatigue and boosting worker satisfaction.

Our manufacturing customers are benefiting from cost of quality optimization, improving first time yield, reducing training & ramp-up time, and radically changing the way they do continuous improvement by using nFlux Acuity™.

Rework Reduction

nFlux Guide™ minimizes errors and deviations, reallocating time from corrections to production, boosting output.

Scrap Reduction

Early error detection means fewer resources lost to flawed products, conserving assembly resources (materials, basic components, electricity, gases, solvents, etc.)

Flexible Poka-Yoking

AI and vision systems modernize error-proofing, improving adaptability and reducing setup time for new stations.

Reducing Quality Escapes

Real-time guidance and verification cut down on defects, avoiding penalties and aiding in dispute resolution with video-based birth certificates.

Training and Ramp-Up Time Reduction

Digital instructions with visuals and step-by-step guidance speed up the learning curve for new product assembly and apprentices.

Capturing Tribal Knowledge

Digital work instructions enhanced with the corresponding video recordings persists knowledge from experienced workers to prevent know-how loss.

Simplified Transfer of Operations

Leveraging documentation, training and quality control capabilities of the solution manufacturers can relocate assembly activities across lines, factories or countries with agility.

Enhanced Productivity

With reduced resource loss, including rework time, and additional visibility on cycle time, LEAN engineers can further streamline manufacturing operations.

What are our customers saying?

Seeing the AI detect actions in real-time feels like magic. It is gratifying finding companies like nFlux that use technology to aid human workers and not to replace them.

Union's Representative aerospace oem

When people across the company see Guide™ in action they completely get it. I could easily see it becoming the new hammer for assembly workers

head of global excellence at electronics OEM

The simplicity of using AI and machine learning behind Guide™ has the potential of disrupting the incumbents in the field of Automatic Optical Inspection (AOI).

PLANT MANAGER AT ELECTRONICS OEM

nFlux Guide™️ and Acuity™️ suite of manufacturing AI assitance tools is changing the game in quality and productivity.

With less than 6 months of payback time, our customers are finding it a no-brainer to adopt nFlux!

Defect avoidance

34%

Rework Reduction

16%

Ramp up time

-47%

Training time

-52%